What is a good job for engineers and professionals to make ultra clear and precise line indication for all industrial processing works? None of visible laser devices can be compared to a longer wavelength of 980nm made device, such as a infrared line laser module. It projects invisible and intense infrared laser light to the human eye, causing no glare or blinding light, and does not affect worker operations or workshop lighting, making it suitable for high precision automated production lines. Usually infrared laser line generator makes invisible line marking, causing no interference with on site operations. The straight infrared lines are serving as a micron-level processing benchmark, significantly reducing manual positioning errors and improving processing consistency.

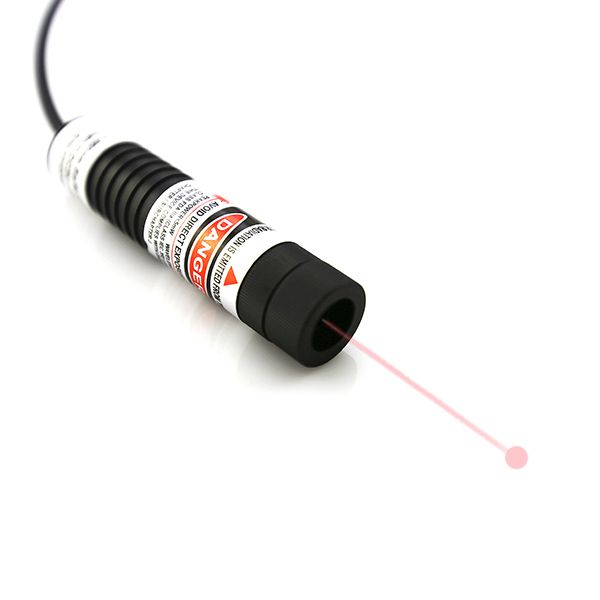

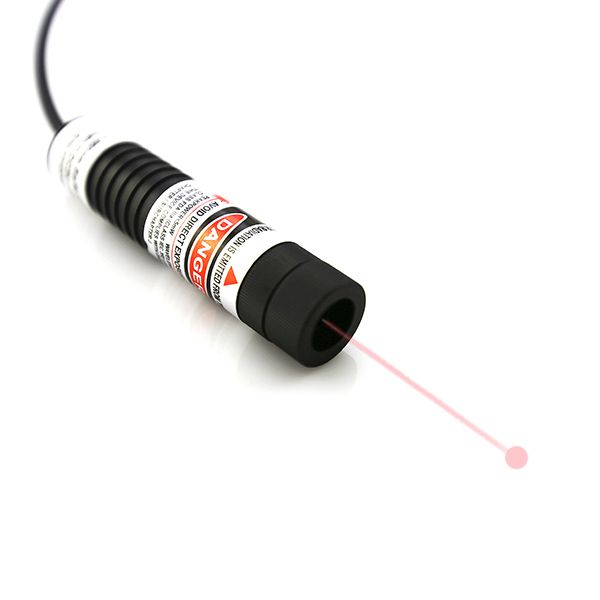

Owing to its longer wavelength than any other visible devices among visible optical spectrum, the 980nm infrared line laser module is highly compatible with machine version and CCD cameras, enabling automatic alignment, automatic correction, and automatic centering, perfectly integrating into intelligent processing equipment. It applies an import 980nm infrared laser diode within 100mW to 500mW and 600mW to 1000mW as its output power, configured with a metal heat sink cooling system inside a durable anodized aluminum alloy housing tube. This infrared laser line generator always gets superior nice heat dissipation and increasing stability infrared reference line projection as long as 10 hours per day. In addition, the infrared band has strong resistant to dust, water, mist and oil, maintaining stable imaging even in dusty environments such as metal processing, welding, and cutting.

In process of long term lasted line positioning work, 980nm infrared line laser module applies a qualified glass coated lens within 10 to 110 degree fan angles, which emits highly straight and fine infrared reference line within 0.5 meter to 6 meters length in use. Together with adjustable focus optic lens, it gets immediately concentrated infrared laser light, and efficient converted infrared reference line thickness, and achievers high level of accuracy infrared line alignment at greater distance and longer time use. This infrared laser line generator is convenient for installation inside machine tools, robots, fixtures, and various automated equipment. Non contact infrared laser line alignment brings no damage to the workpiece, which is suitable for high-precision machining and positioning of precision parts, soft materials, mirror surfaces, transparent parts, etc.

Applications in industrial processing works:

Laser Cutting, Plasma Cutting, Waterjet Cutting Positioning: 980nm infrared line laser module provides cutting center lines and alignment lines for materials such as sheet metal, pipes, fabrics, leather, and glass, enabling rapid alignment, precise cutting, and improved cutting path consistency.

Metal Bending, Stamping, and Die-casting Alignment: It projects IR reference lines onto bending machines, punch presses, and die-casting machines to achieve mold alignment, workpiece positioning, and angle calibration, reducing manual alignment errors and improving forming accuracy and yield.

Welding Positioning (Automated Welding/Robotic Welding): 980nm infrared alignment laser serves as a weld seam alignment mark in spot welding, arc welding, laser welding, and soldering processes, assisting in workpiece docking and weld seam tracking, improving welding accuracy and weld quality stability.

Category: infrared laser module

Precise Positioning 808nm Infrared Laser Diode Module In The Medical Field

In any type of clear and precise dot indication for all medical treatment and positioning fields, not able to rely on a simple infrared laser pointer or any other manual dot projecting tool, it would be a much better solution to apply a long wavelength made device of a 808nm infrared laser diode module. It always keeps work with moderation IR laser light emission from an import near IR band laser diode, allowing it to penetrate the skin surface and act on subcutaneous soft tissue without the risk of UV/visible light damage. Under operation with correct output power and operating voltage electric power source supply, this direct diode emission made infrared dot laser alignment tool meets the safety standards for medical laser equipment and is suitable for contact-based diagnostic and treatment scenarios.

Basically this 808nm infrared laser diode module applies a AC/DC adapter, not spending prior time on battery change, it can provide continuous infrared light source generation from beam aperture. In addition, it can also be designed with pulse power supply so as to fulfill different users’ need. Being made with an import 808nm infrared laser diode within 5mW to 400mW and 500mW and 1000mW output power, this infrared dot laser alignment is designed with different thermal emitting part. Usually lower power adopts inner cooling system, and high power adopts separate metal heat sink cooling system, thus it always gets sufficient space leaving for tube heat dissipation, and achieves ultra stable and reliable infrared light source and IR dot generation in long term use. It is unaffected by overheating and over current impact as well.

Being made with an adjustable focus optic lens and qualified glass coated lens, 808nm infrared laser diode module can easily make high concentration IR laser light emission, and efficient conversion of increasing accuracy and brightness infrared dot projection at greater distance. The point like IR light spot has strong focusing ability, uniform spot energy without distortion, and precisely target lesions/application points. It is adapted to the energy requirements of different treatment sites. Featured by high electric optical conversion efficiency, this infrared dot laser alignment also gets no significant thermal drift during long term continuous light output, meeting the high-frequency clinical use requirements of medical equipment and reducing equipment maintenance frequency.

Applications in medical treatment fields:

Core Light Source for Laser Therapy Equipment: As the core light-emitting unit of infrared therapy instruments and pain relief devices, the dot-shaped light spot precisely acts on painful areas such as joints, muscles, and fascia.

Core Module of Laser Hair Removal Device: 808nm is the golden wavelength for hair removal. The dotted light spot precisely targets the hair follicle root, selectively absorbing melanin and causing thermal damage, thus putting the follicle into dormancy.

Medical Testing Equipment Light Path Excitation: 808nm infrared laser diode module is integrated into biochemical analyzers and immunoassay devices, it serves as an infrared dotted excitation light source, precisely exciting the fluorescence signal of test reagents.

Precision Diagnosis and Treatment in Ophthalmology/Dermatology: In low-energy ophthalmic therapy and the repair of small lesions in dermatology, the dotted light spot precisely targets the area around the eyes and delicate areas of the face.

Rehabilitation Equipment Supporting Light Source: When used with rehabilitation robots and limb therapy equipment, the dotted light spot precisely targets the damaged limb area following rehabilitation movements.

Minimally invasive surgical positioning aids: In some minimally invasive surgical procedures, infrared alignment laser dot-shaped positioning markers are used to accurately mark surgical incisions and lesion locations, providing visual references for surgical instrument operation and improving the accuracy of surgical procedures.

General Applications of 980nm Infrared Laser Line Generator in Scientific Research

In those of special scientific research fields, a lot of engineers and professionals would prefer to operate a longer wavelength device of a 980nm infrared laser line generator. It is primarily used in the fields of optics, materials science, biomedicine, 3D measurement, and optical communication. It always applies qualified import 980nm infrared laser diode and glass coated lens inside a durable metal housing tube, configured with basic thermal emitting design, this direct diode emission made infrared laser module enables high precision IR line light source emission, strong resistance to light interference. When it makes easy integration with scientific experimental device or equipment, it always enables highly precise, fine line indication, applicable for multi-disciplinary precision experiments and long-term measurements.

This 980nm infrared laser line generator applies an AC/DC adapter as its electric power source, thus it always able to make quick response and good direction IR line projection onto any working surfaces. It applies an import 980nm infrared laser diode with 100mW to 1000mW, after special use of inner cooling system or separate metal heat sink design, it always gets superior nice heat dissipation, and ultra long time lasted infrared reference line projection within 10 hours. When infrared line laser module gets small laser beam divergence of less than 2mrad, it can get ultra fine line width of ≤1mm at 1 meter, meeting the needs of micron-level experiment. The 980nm invisible light is resistant to sunlight and indoor light interference, significantly improving signal-to-noise ratio with narrowband filters, suitable for continuous day and night measurements and outdoor experiments.

When 980nm infrared laser line generator is applied for biological and experimental safety field, owing to its high penetration IR laser light emission, it also allows easy location in the second optical window of biological tissue with low scattering, and minimal damage to cells and tissues. The invisible light gets no red glare, does not interfere with visual observation and imaging systems. Besides its operation with common DC power supply, this infrared line laser module also supports TTL modulation. This ultra compact size tube mde laser device can be directly installed on an optical platform, suitable for continuous and pulses dual modes and long term experiments.

Core applications in scientific research works:

Optical Experiments and System Calibration: Infrared optical path alignment, line and area array infrared detector calibration, optical platform field-of-view calibration, interference/diffraction experiments.

Materials Science Research: Infrared spectral analysis, material thermal and mechanical property testing, thin film thickness and uniformity measurement, photovoltaic cell PL imaging.

Biomedical Imaging: Upconversion fluorescence excitation, tissue optical window deep imaging, basic research on photothermal therapy. Infrared laser line generator achieves non-destructive, high-penetration, and low autofluorescence interference in vivo monitoring at low power.

3D Measurement and Sensing: Triangulation 3D profile scanning, microstructure and micro-part surface morphology reconstruction, lidar principle verification. The infrared alignment laser line, combined with an infrared camera, quickly generates high-density point clouds, supporting precision measurement and algorithm development.

Optical Communication and Quantum Optics: 980nm infrared line laser module provides a spectrally pure and power-stable source, suitable for fiber coupling and high-speed modulation.

Laser Spectroscopy and Analysis: Laser-induced breakdown spectroscopy (LIBS) elemental analysis, Raman spectroscopy infrared excitation, photoluminescence (PL) testing; provides a high-energy-density line light source, suitable for various spectrometers and detectors.

High Precision Dot Positioning Tool of 980nm Infrared Laser Diode Module

What is an efficient for engineers or professionals to make ultra clear and precise dot indication for those of high precision positioning works? It is far more enough to reach to apply a simple laser pointer or manual dot projecting tool, but making even better job to apply a longer wavelength made device, such as a 980nm infrared laser diode module. It projects invisible and intense infrared laser light from an import 980nm infrared laser diode, equipped with qualified optic lens and thermal emitting system. Whenever this IR dot laser gets constant electric power source supply and proper integration with night version device or equipment, it enables excellent concealment IR laser light emission, which poses no risk of light exposure in security and confidential scenarios, offering higher safety.

Being made with an import 980nm infrared laser diode with different output power range of 5mW to 500mW and 600mW to 1000mW, usually low power infrared laser diode module can meet sensing and fill light requirements, while high power can achieve mild thermal effects, adapting to multi scenario power requirement. After its easy connects with an AC/DC adapter, accepting wide range electric current of 100V to 240V, infrared dot laser alignment always gets highly powerful and intense infrared laser light generation, a small beam divergence angle. After its easy adjustment of laser beam focus lens, it enables highly concentrated energy emission, and high positioning accuracy, suitable for high-precision applications such as ranging and alignment.

In process of long term lasted infrared dot projection, this 980nm infrared laser diode module applies a qualified glass coated lens and glass window in front of beam aperture. It assures low energy consumption and high stability infrared dot projection. In various harsh working occasions, owing to its good thermal control system design, whenever it makes easy integration into small devices, such as wearable devices and miniature sensors, this infrared dot laser maintains stable operation in normal temperature industrial/civilian environments. Whenever users are aware of powerful infrared laser radiation and reflection, it is a key issue to take active laser safety measure and wear proper infrared laser safety goggles, thus it makes good job for all night time security monitoring, industrial automation alignment, laser ranging, and machine vision inspection etc.

Applications in multiple fields:

Security Monitoring: As a core component of infrared fill lights, 980nm infrared laser diode module works with surveillance cameras to achieve covert night vision without visible light, preventing the exposure of equipment location.

Biomedical Field: Used in vein imaging devices to assist medical personnel in quickly identifying subcutaneous veins; adapted to infrared physiotherapy equipment, utilizing the infrared photothermal effect for localized physiotherapy.

Industrial Inspection: 980nm infrared alignment laser is used with machine vision systems to perform component defect detection, size measurement, and positioning; used as the core light source for laser ranging sensors.

Consumer Electronics: Integrated into infrared remote control devices and motion-sensing interactive devices to achieve signal transmission and motion recognition.

Scientific Research and Experimentation: As a basic light source for infrared optical experiments in laboratories, used for material infrared characteristic research, optical sensing experiments, etc.

Applications of Gaussian Beam 808nm Infrared Line Laser Module in Laser Cutting Work

What is a good job for engineers and professionals to make ultra clear and fine line indication in those of laser cutting works, not able to rely on any prior line drawing or printing work, it would be an efficient job to apply a long wavelength made device of a 808nm infrared line laser module for those of night version illumination fields. It is projecting 808nm invisible IR laser light, which does not interfere with the human eye or visible light vision inspection equipment. When it gets constant electric power source supply, not relying on any professional skills, after correct use of output power and optic lens fan angle, this laser line generator makes no visible mark residue, no mistake and noncontact IR line indication for stealth cutting and processing of sensitive materials.

Basically 808nm infrared line laser module applies a qualified glass coated lens within 10 to 110 degree fan angles, equipped with an import 808nm infrared laser diode within 5mW to 1000mW, it enables high penetration and highly powerful infrared laser light source generation at different work distances, low attenuation in dust, smoke, and oil, resisting strong workshop light and electromagnetic interference, with stability superior to visible light sources. It belongs to an industrial-grade module, which can withstand a wide temperature range of -20~60℃ and vibration of 10-2000Hz, suitable for outdoor and heavy-duty processing environments.

When 808nm infrared laser line generator projects highly straight and fine infrared reference line within 0.5 meter to 6 meters length in distance, cooperated with adjustable focus optic lens design, it always enables excellent straightness of the line, positioning accuracy reaches sub-millimeter level. Infrared laser line fineness can be adjusted freely so as to get ideal line alignment accuracy onto different cutting raw material surfaces. When it achieves required cutting width, it can significantly improve bath processing consistency. After the adoption of 16mm, 18.9mm and 26mm diameter tube design for different output power range, this infrared line laser module can be easily installed in confined spaces,achieving high electro-optical conversion efficiency, low power consumption, continuous working life **≥12000 hours.

Applications in laser cutting works:

Cutting Path Positioning Marking: 808nm infrared line laser module projects a reference linear line onto fiber/CO₂ cutting machines and plasma cutting machines, covering the entire cutting line in one pass. It is suitable for cutting metal sheets, PCBs, woodworking, and acrylic.

Machining Tool Setting and Focus Calibration: Used for tool/nozzle height calibration and focus position setting in CNC and laser welding machines, suitable for multi-layer cutting of thick plates and contour tool setting of irregularly shaped parts, improving first-piece yield.

Online Visual Inspection Guidance: 808nm infrared alignment laser is used as a line structured light source to assist in the detection of part dimensions, edge burrs, and cut perpendicularity after cutting, applicable for semiconductor silicon wafer scribing and photovoltaic cell crack detection.

Invisible Pre-marking and Heat-Sensitive Processing: Pre-marking cutting lines on materials such as photoresist, thin glass, and flexible circuit boards without damaging the substrate.

Multilayer Material Alignment and Stacking Cutting: Provides interlayer alignment references for composite materials, multilayer PCBs, and thin film stacking, reducing waste caused by layer misalignment.

Stable Wavelength 808nm Infrared Laser Diode Module Applied For Scientific Research Field

If highly precise dot indication is in serious need for those of night version illumination fields, not able to rely on a simple laser pointer or other manual dot projecting tool, it makes a good job to apply a long wavelength made device, such as a 808nm infrared laser diode module. Employed by an import 808nm infrared laser diode and a qualified optic lens inside a durable metal housing tube, only if it gets constant electric power source supply and basic equipped heat dissipation design, it enables high energy density infrared laser light source generation, and converts into increasing accuracy and brightness infrared laser dot projection at different work distances conveniently. When 808nm infrared dot laser is cooperated with night version device, after its proper integration into night version experimental device or equipment, it enables easy reaching, long term lasted and good direction infrared dot indication continuously.

Usually 808nm infrared laser diode module applies an external AC/DC adapter, not spending extra time on alkaline battery power change, it not only gets larger space leaving for tube cooling down, but also achieves increasing brightness and stability infrared reference dot projection as long as 10 hours per day. Owing to its invisible IR laser light emission, this accessory part is always working together with night version device, involving IR laser camera, black and white camera or CCD camera etc. 808nm infrared dot laser alignment maintains small output wavelength fluctuation range, ensuring consistency of experimental conditions and avoids the impact of wavelength drift on the accuracy of experimental data.

Available with an import 808nm infrared laser diode within 5mW to 1000mW and metal heat sink cooling system inside a high duration anodized aluminum alloy housing tube, 808nm infrared laser diode module also gets special use of adjustable focus optic lens. It enables freely adjusted laser beam focus, thus powerful IR laser light is converted into an increasing accuracy and brightness infrared dot projection at a longer distance. It can be adapted to the diverse laser energy requirements of different scientific experiments. Featured by good uniformity and a small divergence angle, the generated high precision beam focusing meets the positioning and illumination requirements of microscopic experiments. Whenever infrared dot laser alignment is interfacing with various scientific research equipment such as spectrometers, microscopes, and fiber optic couplers, it is adapting to the setup needs of different experimental platforms.

Applications in scientific research fields:

1. Fluorescence Excitation and Spectroscopic Analysis: As a commonly used infrared excitation source in laboratories, 808nm infrared laser diode module is used to excite fluorescence signals in specific materials, enabling qualitative and quantitative analysis of material composition and molecular structure in conjunction with a spectrometer.

2. Optical Experiments and Optical Communication Research: Used for performance testing of infrared optical systems, such as lens transmittance and fiber optic transmission loss detection. It can also serve as a signal emission source for short-range optical communication experiments.

3. Basic Biomedical Research: In cell imaging and tissue optical property research, 808nm infrared alignment laser projects infrared spots to observe the absorption and scattering patterns of near-infrared light in biological tissues, providing data support for the development of new medical devices.

What is The Unique Experience of 808nm Infrared Line Laser Module

What is an efficient job for users to make ultra clear and precise line generation for all night version illumination work fields? It is not able to rely on the prior line drawing or printing works, but making even better job to apply a long wavelength device, such as a 808nm infrared line laser module. It belongs to a near infrared laser device, which makes good use of an import 808nm infrared laser diode and a qualified optic lens inside a durable metal housing tube, and gets constant electric power source supply. Whenever laser line generator projects highly powerful and intense infrared laser light source, it can easily penetrate fog and dust, making sure of ultra clear and precise infrared line projection, suitable for complex industrial and outdoor environments.

Cooperated with an AC/DC adapter, compared to a simple alkaline battery power source made IR laser pointer, the usual use of a 808nm infrared line laser module is able to make long term lasted infrared laser bean and IR reference line projection from beam aperture. It applies an import 808nm infrared laser diode within 5mW to 500mW and high power up to 600mW to 100mW. Owing to its invisible infrared laser light emission to the human eye, this infrared laser line generator should only be used together with other night version machine or device. Its operation can avoid light pollution, suitable for security and confidential scenarios.

Being made with a qualified glass coated lens within 10 to 110 degree fan angles, together with its low laser beam divergence, the usual use of a 808nm infrared line laser module maintains narrow and straight IR line projection with various IR line lengths in continuous use. When it gets special design of adjustable focus optic lens design in front of laser beam aperture, after immediate infrared laser light source concentration, it is converted into small reference error, ultra fine and straight infrared line projection in distance. Whenever IR laser line generator gets correct use of output power and optic lens fan angle, it can make ultra clear and precise infrared line generation, with improving operational accuracy.

Whatever kind of night version precise line positioning work, 808nm infrared line laser module enables low power consumption, more energy efficient and longer battery life compared to the visible light modules. Being made with the durable anodized aluminum alloy housing tube, it also bears wide range operating temperature within -20℃~60℃), infrared alignment laser can be integrated into various devices, and make long term lasted and high stability IR line generation for all night version precise line positioning works.

Applications:

Industrial: Mechanical cutting/welding positioning, automated production line calibration, PCB board alignment;

Security/Surveying: Infrared supplementary lighting, perimeter security early warning line deployment;

Medical: Positioning guidance for physiotherapy equipment, auxiliary aiming in minimally invasive surgery;

Consumer Electronics: Motion-sensing game interaction, infrared touch sensing;

Measurement and Detection: Distance measurement baseline, building horizontal/vertical calibration.

How Can 808nm Infrared Laser Diode Module Be Applied in Industrial Processing

How can precise dot indication work is processing for all night version illumination fields? It is not workable at all to only rely on the use of a simple laser pointer or other manual dot projecting tool at all, however, it makes a better job for professionals to apply a long wavelength made device of a 808nm infrared laser diode module. It projects different type of invisible infrared laser beam from a 808nm infrared laser diode. Cooperated with night version device and constant electric power source supply, cooperated with night version machine or device, and proper installation or integration with night version device or equipment, this direct diode emission made infrared dot laser alignment enables easy reaching, high precision and quick response IR dot generation for all industrial processing works conveniently.

Basically 808nm infrared laser diode module applies a durable anodized aluminum alloy housing tube, cooperated with an import 808nm infrared laser diode within 5mW to 400mW and high power up to 500mW to 1000mW. Owing to its special use of a metal heat sink cooling system design, whatever output power it is selected, it gets larger space leaving for tube cooling down, and achieves ultra clear and stable infrared laser beam and infrared laser dot projection under operation with any other night version device or equipment. Whenever it gets strong penetration under workshop smoke and dust, this infrared dot laser alignment is also not effected by strong light/oil pollution, ensuring continuous and stable operation.

Whenever 808nm infrared laser diode module applies a qualified glass coated lens and glass window in front of laser beam aperture, it generates high transmittance and high photoelectric ability infrared laser light source emission at several miles far away. Owing to its low laser beam divergence, together with adjustable focus optic lens design, after its immediate infrared laser light source concentration, 808nm infrared dot laser alignment enables increasing accuracy and brightness infrared reference dot projection at a longer distance, and achieves positioning error as low as micrometers. This industrial stabilized laser device gets good performance of vibration resistant, resistant to high and low temperatures (common operating range -20℃~60℃), long service life.

General applications in industrial fields:

Machinery Positioning: 808nm infrared laser diode module is marking cutting/drilling reference points on lathes, milling machines, etc., enabling rapid tool setting.

Welding/Cutting Alignment: Precisely indicating weld/cutting paths during laser spot welding and fiber optic cutting, improving operational accuracy.

Automated Calibration: Position calibration and trajectory positioning for robotic arms, conveyor lines, etc., ensuring consistency in automated processes.

Assembly Assistance: 808nm infrared alignment laser is providing visual alignment marks during precision parts assembly, reducing assembly errors.

High Penetration Gaussian Beam 808nm Infrared Line Laser Module

In those of night version precise line positioning fields, not workable at all to only rely on prior line drawing or any other visible laser devices, it would be a much better solution to apply a 808nm infrared line laser module. It applies a long wavelength 808nm infrared laser diode and a qualified glass coated lens inside a highly durable metal housing tube, which enables high quality Gaussian IR laser beam emission at long extending distance, but also enables highly efficient conversion of increasing accuracy and brightness infrared reference line projection for multiple night version precise line positioning works conveniently.

When 808nm infrared line laser module applies an AC/DC adapter as its electric power source, compared to formal alkaline battery power source, it enables long term lasted IR line projection. 808nm infrared laser light has better penetration of smoke and dust than visible light and is less susceptible to interference from ambient visible light (such as sunlight and lighting), making it suitable for complex industrial or outdoor environments. When it applies an import 808nm infrared laser diode within 5mW to 500mW and high power up to 600mW to 1000mW, cooperated with a metal heat sink cooling system, the basic use of an infrared laser line generator has just got superior nice heat dissipation, and ultra long term lasted infrared line indication for a quite long time.

In practical precise IR line positioning work, cooperated with a qualified glass coated lens within 10 to 110 degree fan angles, generally 808nm infrared line laser module enables highly concentrated infrared laser light indication, and ultra clear and fine infrared line marking onto different working surfaces. It emits different infrared reference line within 0.5 meter to 6 meters length. In those of long term lasted infrared line alignment work, this infrared laser line generator maintains stable output optical power, high straightness and high linear quality infrared line generation, meeting high-precision positioning requirements.

Available with durable and ultra compact anodized aluminum alloy housing tube design, usually 808nm infrared line laser module bears wide range operating temperature range of -20°C to 60°C, adapting to both high and low industrial environments with robust performance. Being made with different tube diameter of 16mm, 18.9mm and 26mm for different output power range, it enables superior nice thermal emitting and ultra stable IR line generation. Cooperated with adjustable focus optic lens design, this infrared alignment laser enables efficient conversion of increasing accuracy and fineness IR line generation at greater distance.

The core applications of 808nm infrared line laser modules (invisible light, requiring night vision equipment for observation) are concentrated in scenarios requiring precise infrared positioning and marking, primarily including:

Industrial processing: Path marking for cutting and engraving metal/non-metal materials, and PCB soldering positioning.

Security monitoring: infrared alignment laser is assisted focus for infrared surveillance cameras and warning area demarcation (such as infrared warning lines for perimeter protection).

Medical: Infrared illumination area positioning for physical therapy equipment (such as treatment range markings on certain rehabilitation equipment).

Automated equipment: Robotic inspection, material positioning and path guidance for automated assembly lines.

Scientific research: Infrared baseline calibration for optical testing and biological sample observation.

Unique Use of 808nm Infrared Laser Diode Module For Industrial Inspection

What is an efficient job for users to make ultra clear and precise dot indication for all night version illumination fields? It might not be workable at all to only rely on prior manual dot projecting tool, however, under constant technical innovation of advanced 808nm infrared laser diode tech and a qualified glass coated lens inside a durable anodized aluminum alloy housing tube, it is manufactured into a professional dot measuring tool of a 808nm infrared laser diode module. Usually it gets constant electric power source supply from a 5V, 9V 1000mA DC power supply. Not affected by ambient light such as visible and UV rays, stable signal output is maintained in strong outdoor sunlight, under workshop lighting, or in high-temperature, smoke-filled environments, ensuring detection accuracy.

In practical precise dot measuring works, 808nm infrared laser diode module applies an import 808nm infrared laser diode within 5mW to 500mW and high power up to 600mW to 1000mW as its beam emitting source. It gets high photoelectric ability IR laser light source emission. In addition, when it is required to make long term lasted IR dot indication, it has been made with a metal heat sink cooling system and APC, ACC driving circuit board inside a durable anodized aluminum alloy housing tube. In practical long term lasted infrared dot indication, this infrared dot laser alignment tool always maintains stable infrared laser beam emission, and ultra stable and clear infrared reference dot projection as long as 10 hours per day. It also makes sure of noncontact IR dot projection with the workpiece surface, preventing scratches and wear on precision parts (e.g., electronic components and polished metal parts). It is also suitable for high-temperature, high-pressure, and other environments where close contact is undesirable.

When 808nm infrared laser diode module applies a qualified glass coated lens and a glass window in front of beam aperture, on occasion that is used under dust, rain, water or other moisture condition, it still exhibits distinct differences in reflection/transmission across different materials, enabling precise material differentiation and identifying subtle defects, ensuring a balanced inspection depth and accuracy. After its projection of high transmittance, high energy density and low heat generation infrared laser light emission at several miles far away, this infrared dot laser alignment tool can still make ultra stable IR dot generation, which can be working together with industrial machine or device, reducing equipment energy consumption and maintenance costs.

General use in industrial inspection fields:

Defect Detection: By emitting an 808nm infrared spot to illuminate the surface of materials such as metals and plastics, an infrared camera is used to capture the reflected/transmitted light signals to identify subtle surface defects such as cracks, scratches, and bubbles (which are difficult to detect with the naked eye or visible light).

Thickness/Distance Measurement: 808nm infrared laser diode module utilizes the rectilinear propagation characteristics of infrared light, time-of-flight (TOF) or triangulation is used to non-contactly measure the thickness of materials (such as films and plates), the spacing between workpieces, or the positioning distance of equipment.

High-Temperature Environment Monitoring: In high-temperature production lines (such as steel and glass manufacturing), 808nm infrared alignment laser light is less susceptible to interference from high-temperature ambient light and can penetrate the mist/smoke generated by high temperatures to monitor the shape, position, or surface temperature distribution of workpieces.

Material Identification and Sorting: By leveraging the differences in reflectivity of 808nm infrared light across different materials, sensors can be used to identify material types (such as metal and non-metal, different types of plastics) for automated sorting.