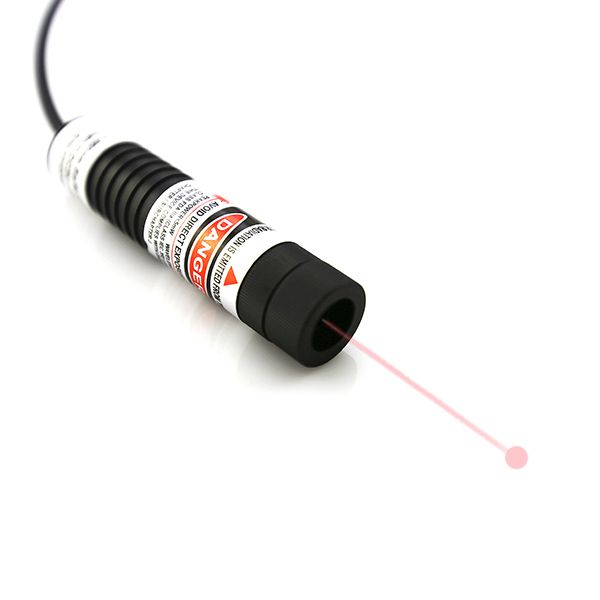

What is an efficient job for users to make ultra clear and precise cross line projection for those of night version illumination work fields, not easy to rely on any prior cross line drawing or printing works, it would be a much better solution to apply a long wavelength made device of a 808nm infrared crosshair laser module. Owing to its adoption of an import 808nm infrared laser diode and a qualified glass coated lens inside a high duration metal housing tube, only if it is cooperated with any other night version machine or device, this ultra compact structure made infrared cross laser alignment tool enables high precision, high brightness and high accuracy two perpendicular IR lines generation at long extending distances conveniently.

The advanced use of an import 808nm infrared laser diode gets wide range output power of 5mW to 500mW and high power up to 600mW to 100mW. In practical precise cross line measuring works, this infrared crosshair laser module should be working with other night version device, such as CCD camera, black and white camera or infrared camera etc. It is equipped with a metal heat sink cooling system inside different dimension anodized aluminum alloy housing tube, this infrared cross laser alignment tool gets superior nice heat dissipation, easy installation or integration, quite easy reaching and highly precise two perpendicular infrared lines generation at different work distances. Owing to its high penetration and low interference IR laser light emission, the genuine infrared cross line projection has no effect by visible light. It has better penetration than visible light lasers in dusty and misty environments, making it suitable for complex industrial and outdoor scenarios.

When 808nm infrared crosshair laser module applies a qualified glass coated lens with 10, 15 and 110 degree fan angle, after its connects with 5V, 9V 1000mA DC power supply, it enables high efficiency conversion of increasing accuracy and brightness two perpendicular IR lines at long work distance constantly. It always takes low energy consumption and low manual labor force input. Being made with APC, ACC driving circuit board design, whatever output power it is selected, this infrared cross laser alignment is performing well with constant IR cross line projection, and long serving lifetime of more than 8,000 hours. After selection of both of output power and optic lens fan angle, cooperated with adjustable focus optic lens design, it assures increasing accuracy and brightness cross line projection within several miles far away.

General use of 808nm infrared cross line laser module:

Industrial Manufacturing: Used in machine tool processing, metal cutting, and PCB board positioning, providing a precise infrared crosshair reference to assist operators in workpiece alignment.

Building and Decoration: Used in conjunction with a level, infrared cross laser alignment achieves vertical/horizontal positioning for wall scraping, tile laying, and ceiling installation, replacing traditional chalk lines.

Medical: Used as an infrared aiming reference in physical therapy equipment to assist in locating the treatment area (such as laser physical therapy devices); or for sample positioning under a microscope.

Security Monitoring: infrared alignment laser is integrated into surveillance cameras, infrared crosshairs are used to calibrate the monitoring range and assist in adjusting the camera angle and focus.

Research and Experimentation: Used as a non-visible light reference in optical experiments and material testing, marking the optical path or sample inspection area.